Ростов-на-Дону, Ростовская область, Россия

с 08.07.2013 по настоящее время

Ростов-на-Дону, Ростовская область, Россия

Шахты, Ростовская область, Россия

УДК 624.138 Повышение несущей способности грунтов. Укрепление грунтов. Уплотнение грунтов. Укрепление грунтов инъецированием растворов (стабилизация)

ГРНТИ 67.01 Общие вопросы строительства

ББК 308 Монтаж, эксплуатация, ремонт машин и промышленного оборудования

Основная цель работы — увеличение коэффициента трения между частицами в испытуемом образце путем формирования вертикальных армоэлементов из крупного гравия в мелком песчаном грунте. Определение прочностных характеристик песчано-гравийных смесей выполнялось на образцах, отобранных в Ираке на неустойчивых берегах реки Тигр, на которых формировались трещины, происходили оползни и обвалы. Посредством испытания образцов на сдвиг исследовано влияние диаметра столба крупного заполнителя и размера заполнителя на увеличение угла внутреннего трения. Установлено, что распределение частиц по размерам и форма частиц влияют на характеристики сжатия, проницаемость и прочностью грунта на сдвиг. Предыдущие исследования моделировали коэффициент пористости с точки зрения влияния распределения частиц по размерам, но не учитывали влияние формы частиц в этом параметре. В этой работе исследуется влияние трех разных размеров крупного заполнителя на минимальный коэффициент пористости в зависимости от распределения частиц по размерам. Эксперименты показали, что при увеличении количества мелких частиц минимальная пористость снижается. Чем более неправильной была форма частиц, тем труднее было частицам соприкасаться друг с другом, и тем больше было расстояние между ними. На основе экспериментальных данных построены графики, отображающие связь между прочностью на сдвиг, углом внутреннего трения и распределением частиц по размерам.

угол внутреннего трения, испытание на прямой сдвиг, пористость, армоэлементы из гравия, мелкозернистый песчаный грунт, устойчивость склонов

Introduction

A number of researchers have investigated the behavior of stone columns through theoretical, experimental, and field studies. According to Ambily and Gandhi (2007) [1], Of all the methods that may be used to improve in situ ground conditions, columnar inclusions are thought to be one of the most flexible and economical ground quality management techniques. Columns made of stone, grainy material, sand that has been compacted, columns made of gypsum or cement, or structures similar to these may all be used as columnar inclusions since they are all strong and resilient to soil deposits. Columns made of stones there have frequently been utilized in unstable deposits to increase load-bearing capacity, reduce the amount of settling experienced by structural bases, and improve consolidated settlement due to a decrease in flow route lengths. These goals may all be accomplished through the use of stone columns. Stone columns have also been used to support structural foundations. Another significant benefit of using this technology is the ease with which its building may be accomplished. The type of material and the size of the particles of the material used for a column are two of the most important characteristics in the construction of stone columns.

In clay soils, course sand columns are often utilized for the purpose of researching how the presence of such columns affects the strength of the soil. The practice of using course sand columns to enhance the geotechnical qualities of soft saturated cohesive soils is used extensively in many different parts of the world. The high compressibility (cc range from 0.19 to 0.44) and low undrained shear strength (cu < 40 Kpa) of soft soils are the defining characteristics of this kind of topography (Brand and Brenner, 1981) [2]. Both the capacity for bearing and the settling of soft soil that has been strengthened with sand columns depend on a variety of different conditions. These include the number and arrangement of sand columns on the site, their size and pattern of construction, the area replacement ratio, the amount and pace at which load is applied, and the circumstances surrounding the additional material's deployment. Other factors include the area replacement percentage and the weight of the load.

The backfill materials play the most important role in providing the columns with their stiffness. Clayey soils with undrained shear strengths between 15 and 50 KPa are ideal for this method because they have the greatest potential for success (Barksdale and Bachus, 1983; Juran and Guermazi, 1988) [3, 4]. On the other hand, it is not a viable option in soils that are more compressible since these soils do not offer enough lateral confine.

Soft clays' geotechnical properties, particularly their mechanical properties, such as increasing load-bearing capacity, reducing settlement, and minimizing the creation of additional pore water pressure throughout loading, have been improved by the use of stones or sand columns (Maakaroun et al., 2009) [5]. When installing sand columns as vertical drainage in soil improvement scenarios, the potential reinforcing impact that these columns might have in terms of increasing the soil's carrying capacity is sometimes disregarded during design.

In the past, there have been issues with laboratory studies on coarse-grained soils because the test specimens were of inadequate size. In the majority of instances, the large grain size is limited to less than 10 millimeters, and tests are carried out on the finer percentage of the soil using a technique that is popularly known as the scalping method. In a couple of other scenarios, the same parallel grading curve is utilized as a model of the original soil; this approach, which is called a comparable grading methodology, was designed to deal with these sorts of problems. Also, in both ways, a portion of the soil must be ignored, which might have an effect on its mechanical qualities. Using a large scale in triaxle and direct shear tests is an alternative method for evaluating soils with greater particle sizes and calculating shear strength values. These studies have been used by a number of researchers in order to explore the mechanical behavior of soils with coarse-grained particles. Fragaszy et al. [1990 and 1992] [5, 7] These studies have been used by a number of researchers in order to explore the mechanical behavior of soils with coarse-grained particles. They came up with the concepts of near-field density as well as far-field density. In the near-field, the density of the soil matrix was defined as the density of the soil matrix when it was located in close proximity to the huge particles. On the other hand, in the far-field, the density of the soil matrix was defined as the density of the soil matrix when it was located at a substantial distance from the enormous particles. When big particles are suspended in a finer matrix, it was shown that the static strength of the combination is determined by the density of the distant field. In addition, they observed that an increase in the proportion of gravel affects the soil's far-field density and shear strength. Evans and Zhou [1995] [8] subsequently demonstrated this for the cumulative repeated shear strength of sand gravel. Numerous studies have shown that the gravel component enhances the static shear strength of soil mixes (composed of sand and gravel) when they are in the floating stage, including Yagiz [2001] [9], Vallejo [2001] [10], and Kokusho et al. [2004] [11].

Experimental Work

Using the direct shear test, the research relied on experimental methodology to examine soil attributes. For the coarse aggregate model utilized in this work, it was necessary for calculating the size of aggregates with an outer diameter of less than 12 mm. Because of the limited sample size of the cell dimensions (60 mm x 60 mm x 30 mm), this is regarded as one of the greatest obstacles faced in the research of the influence of coarse aggregate with large dimensions. The procedure relied on mechanical examination of the use of rough aggregate with the field density in the specimens being tested to determine the quantity of actual change in the field density. Additionally, the method required the employ of columns of rough aggregate with sizes larger than the column diameter and gradients bigger than the rough aggregate gradient.

Work that varies from earlier studies by drilling columns into the ground to increase the depths of aggregates within soil layers, lowering the overall amount of aggregates, and reducing the influence of deformation on the soil characteristics to be enhanced.

According to the results of various studies that were conducted in the past, the only impact that the addition of coarse aggregate to sand soil had was to increase the frictional coefficient of the soil. This was the only effect that the addition of coarse aggregate had. Evans and Zhou [1995] [8] accomplished this task, and their solution relied on combining coarse aggregate with each layer of the soil model. However, they neglected the density and cohesion of the models to achieve their goal of improving the soil's properties.

- Direct shear test using the shear device, ASTM D 3080 - 89:

A device that is capable of calculating the amount of friction angle between the soil particles, as well as measuring the degree of cohesion and adhesion that exists between the soil granules, is an instrument that can be used to determine how much pressure is being exerted on the different layers of soil. This may be accomplished by using the device. Additionally, the instrument calculates the pressures exerted on the various levels of the soil. The tool is made up of a circular meter that measures the amount of stress that the tool supplies to the soil as well as user-installed forces that transform those forces into pressure layer forces [12]. Figure 1 shows the tool in general as well as its parts. The apparatus is used to measure the degree of stress that is delivered to the soil by the apparatus.

Figure 1. Direct Shear device

To determine the shear strength of consolidated and drained fine sand soil, a test was conducted using a direct shear machine with a maximum sheer force of (5000 N). With a speed range that can be adjusted from (0.00001 to 9.99999 mm/min) and a digital speed display, the Digital Shear Test Machine is controlled by a high-resolution stepper motor and worm reduction unit. The vertical force is applied to the specimen in a direct manner by use of a load frame that contains weights, and this force has the potential to be increased by means of the beam loading system on the shear testing machine. When using a device with a 10:1 lever ratio, it is able to support a load of up to 50 kilograms of weight, which enables the total specimen test load to vary from (500 N to 5000 N).

A load-displacement measuring tool and a shear box assembly with slotted steel weights are included with the machine. It is possible for the device to be analog with dial gauges and a load ring or electronic with data collecting, displacement transducers, a processing load cell, and a system for obtaining data.

The electronic components are protected by a modern, molded enclosure that has a large LCD display as well as a keyboard. This enclosure also houses the circuits.

- SIEVES, ASTM D 422: employing a number of different soil sieves with a range of different degrees and sizes of clamps in Figure 2.

|

No. |

#4 |

#8 |

#10 |

#20 |

|

mm |

4.75 |

2.36 |

2 |

0.841 |

Figure 2. Sieves analyses

Sample and Process for Preparation

With the aid of ASTM 3080-98, sometimes referred to as the Basic Test Process for Direct Shear Test of Soils Under Consolidated Drained Conditions, the model was created. The height of the model is divided into three levels, and then using a certain hammer, the total weight of each level is calculated according to the required density. As indicated in Figure (3), the column model is fitted with a cylinder of differing diameters and 1 mm thickness, it is positioned in the test mold's center.

As can be seen in Figure 1, the specimen cell was put into place in order to conduct the direct shear test. This process is performed several times, with each iteration taking into account the aggregate dimensions, column diameter, and mixture ratio.

Figure 3. Specimen preparation

Results and Data Analysis

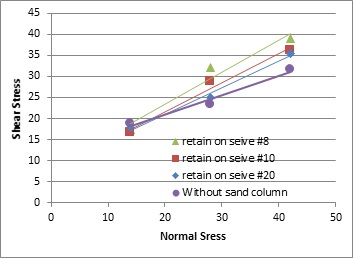

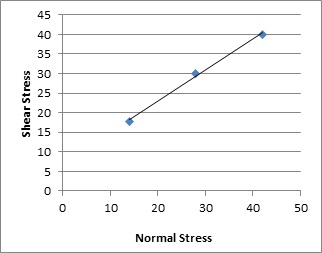

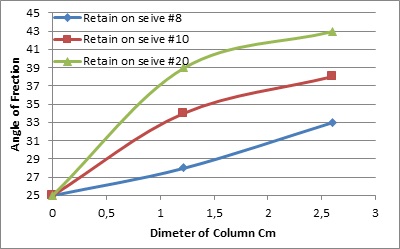

A direct shear test is used to study the shear strength properties of six various materials. In this particular test, the normal stress is varied from 14 to 42 Kpa, and the diameter of the sand column is varied from 1.22 to 2.6 centimeters at each of the three distinct diameters. We observed an increase in the value of the friction angle with increasing aggregate diameter after conducting tests on a sample of field soil and comparing the results to those of soil samples with an improved coefficient of internal friction angle by using aggregate with three different diameters of particles as retained on sieve no. (8, 10, and 20) and having the column area reach 4.5% from the test area of the specimen (1.22 cm diameter column), as depicted in Figure (4).

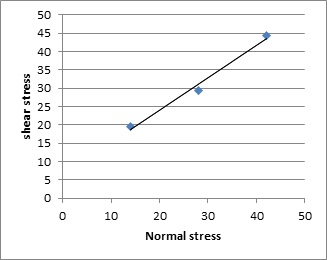

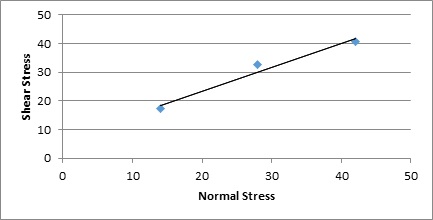

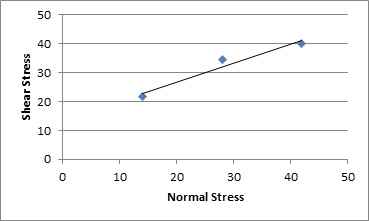

The utilization of mixed aggregates in equal proportions is shown in Figures 5 and 6, both of which have an equivalent column area (4.5%) replaced with aggregate. These figures combine the three particle sizes and mixed aggregates with regard to mixing to the ratio of the improved coefficient of friction. By using mixed aggregates in a ratio equal to the three particle sizes used, this is shown.

Figure 4 .Effect size particles in sand column

with 4.5% area replaced on friction angle

Figure 5. Effect uniform mixing particles in sand column

with 4.5% area replaced on friction angle

Figure 6. Effect non-uniform mixing particles in the sand column

with 4.5% area replaced on friction angle

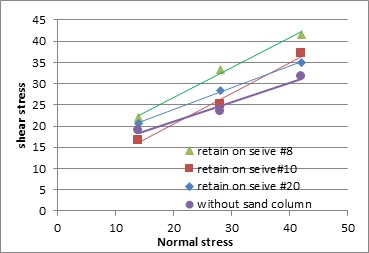

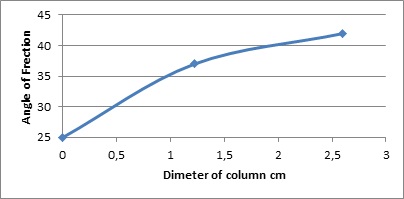

According to Figure (7), the diameter of the aggregate utilized had an inversely proportional effect on the soil's coefficient of friction, showing an increase in the area of aggregate columns and a 10% deviation from the test area. I Two Figures 8 and 9 show that using mixed aggregates in proportionate mixing improved the coefficient of friction for a 2.6 cm diameter column whenever compared to using particles of the same size.

Figure 7. Effect size particles in sand column

with 10% area replaced on friction angle

Figure 8. Effect uniform mixing particles in sand column

with 10% area replaced on friction angle

Figure 9. Effect non-uniform mixing particles in the sand column

with 10% area replaced on friction angle

-Effect of coarse sand column diameter on internal friction angle:

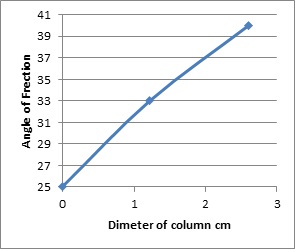

The considerable impact that the width of the coarse sand column has on the internal friction angle of the soil grains is seen in Figure 10. Notably, the internal friction angle for the remaining coarse sand on sieve no. 8 was 28° as compared to the diameter of the coarse sand column (1.22 cm), whereas the angle of internal friction for the 2.6 cm diameter sand column, which supplanted a larger area, was 33°.

- Effect of the mixing ratio of coarse sand on the internal friction angle:

Figure 11 depicts the relationship between the amounts of internal friction soil and the quantities of mixing coarse sand columns. As a consequence of using coarse sand columns, we observe an improvement in the angle of internal friction for the soil that was used, with a ratio that becomes better for all sizes.

Figure 10. Effect the diameter and size of particles of coarse sand column

on angle of friction

Figure 11. Effect the non-uniform mixing of particles size

in different diameter of coarse sand column on angle of friction

Figure 12 shows them adding three different sizes of coarse sand to improve the soil. The coarse sand was mixed in at an identical rate. This correlation between an increase in the value of internal friction in the soil and a decrease in the percentage of voids in the soil led to an enhancement in the properties of the soil.

Figure 12. Effect the uniform mixing of particles size

in different diameter of the coarse sand column on the angle of friction

Summary and conclusion

The purpose of the research was to investigate whether or not it would be possible to improve the physical characteristics of fine-sand soil, more precisely those characteristics of soils that were produced as a result of the action of river deposits, the likes of which may be visible on the shoulders of rivers that have poor soil cohesion. The Tigris River, which was located in a region that was prone to fractures and landslides, was the source of some of the samples that were gathered. It was discovered that the soil had been formed by the sediments made by the river, and based on the findings of a sieve analysis test, it is possible that the soil should be categorized as fine sand soil. This conclusion was reached after it was discovered that the soil was formed from river deposits.

In this work, a laboratory test method was used to calculate and analyze the results of the study. An investigation was carried out to determine the viability of enhancing the quality of the soil and cutting down on the number of collapses that take place on river shoulders or soil barriers. By adding coarse aggregate columns with three sizes and two diameters, the angle of the internal friction coefficient in the soil could be raised. In Figure 1, we notice that the direct shear resistance has increased from 32 to 40 KPa with an increase in the diameter of the aggregate used in the columns each time a larger diameter is used, as the size of the aggregate increased from sieve size No. 20, 10 to 8. The direct shear resistance increases every time. The three sizes of coarse aggregate were mixed, but using various mixing techniques, to add the aggregate column in Figures 2 and 3. We note that the regular mixing method is more effective than the irregular mixing method, as the direct shear resistance in the regular mixing method reached 45 kPa, while the irregular mixing method reached 41 kPa. Increasing the diameter of the aggregate column gives clear readings by increasing the direct shear resistance. Compare Figures 1 and 4 for different aggregate sizes. Analysis of the effect of increasing the size of the aggregate used in stabilizing the soil in a cycle also gave good results in increasing the amount of the angle of internal friction of the soil; in Figure 7, the angle of internal friction increased. From 33° to 43° degrees for each size of coarse aggregate that has been added to the soil. Figures 8 and 9 show the effect of the method of mixing the aggregates on the internal friction angle from 39.5° to 42.5°. If we compare Figures 2 and 3 or Figures 5 and 6, we notice the extent of the effect of adding aggregates with a different gradient, and this in turn led to a reduction in the number of air gaps, which increased the shear resistance of the soil.

To get more realistic results and closer to what actually happens in the real world, the field density was kept the same as in the laboratory. From the results of this, the internal friction coefficient of the soil was raised, and the critical condition or peak friction angles in combination with a lower void ratio were found to be related to an increase in soil stability over time.

1. Ambily, A.P., and Gandhi, S.R.,” Behavior of Stone Columns Based on Experimental and FEM Analysis”, Journal of Geotechnical and Geoenvironmental Engineering, vol.133, 2006, pp.405-415.

2. Brand E.W. and Brenner R.P., (1981), “Soft Clay Engineering.”, Elsevier Scientific Published Company, Amsterdam.

3. Barksdale, R.D. and Bachus, H.G., (1983), “Design and Construction of Stone Columns.”, Dept. of Transpiration, Federal Highway Administration Report, USA report No. FHWA/RD 83/026.

4. Juran, I. and Guermazi, A. (1988), “Settlement Response of Soft Soils Reinforced by Compacted Sand Columns.”, Journal of Geotechnical Engineering, ASCE, Vol. 114, No. 8, pp.930-943.

5. Maakaroun, T., Najjar, S.S. and Sadek, S.2009.Effect of Sand Columns on the undrained load response of Soft Clays. Journal of Geotechnical and Geoenvironmental Engineering. (ASCE).

6. Fragaszy, R.J., Su, W. and Siddiqi, F.H. (1990). "Effect of oversized particles on the density of clean granular soils." Geotech. Test. J., 13(2), 106-114.

7. Fragaszy, R.J., Su, W., Siddiqi, F.H. and Ho, C.L. (1992). "Modeling strength of sandy gravel." J. Geotech. Engrg. Div., ASCE, 118(6), 920-935.

8. Evans, M.D. and Zhou, S. (1995). "Liquefaction behavior of sand-gravel composites." J. Geotech. Eng. Div., ASCE, 121(3), 287-298.

9. Yagiz, S. (2001). "Brief note on the influence of shape and percentage of gravel on the shear strength of sand and gravel mixture." Bul. Engrg. Geol. and Env, 60(4), 321-323.

10. Vallejo, L.E. (2001). "Interpretation of the limits in shear strength in binary granular mixtures." Can. Geotech. J., 38(5), 1097- 1104.

11. Kokusho, T., Hara, T. and Hiraoka, R. (2004). "Undrained shear strength of granular soils with different particle gradations." J. Geotech. And Geoenv. Engrg, ASCE, 130(6), 621-629.

12. ASTM D3080-1998, “Standard Test Method for Direct Shear Test of Soils Under Consolidated Drained Conditions”, American Society for Testing and Materials.